With over 50 years experience in the grain and seed industry Jastec Sheetmetal along with our parent company Jas Smith Machinery is the place to go for all your grain handling equipment.

Our team of skilled tradespeople can design and manufacture all your grain handling requirements including:

- Customised Design

- Fabrication

- Construction

- Installation

- Maintenance

- Repairs.

To complete your grain processing plant, we can manufacture and install:

- Processing Plants

- Bucket Elevators

- Drag Chains

- Belt Conveyors

- Tube Conveyors

- Augers

- Screw Conveyors

- Seed Mixers

- Diverters

- Storage Bins

- Hoppers

- Pneumatic Slide Gates

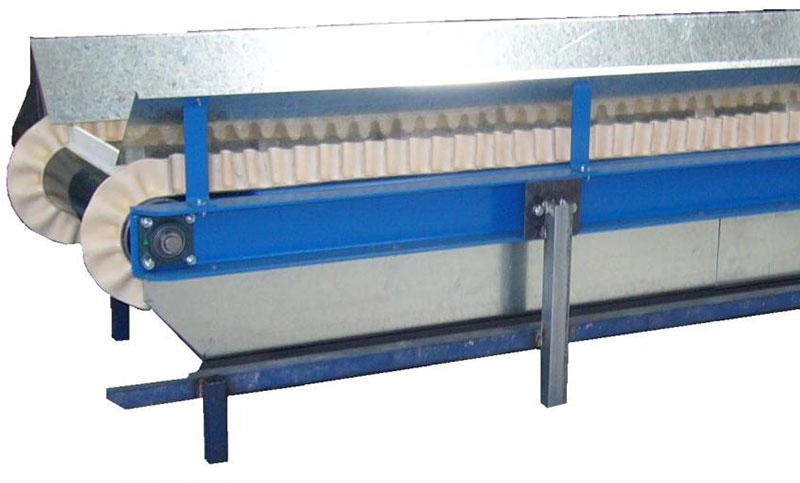

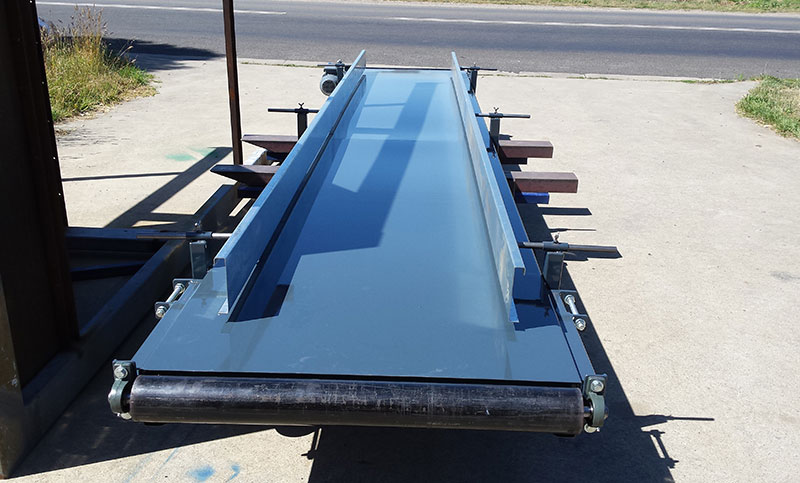

Belt Conveyors

High performance belt conveyors are manufactured as an alternative to augers or screw conveyors for specialised application. These have been used in applications where the auger or screw conveyor may cause unwanted damage to the product.

Typical applications would include the handling of pulse grains such as beans, peas, legumes, potting mix, mulch, stock feed pellets, bulky stock feed mixes and citrus pulp.

Chutes and Diverters

Chutes and Diverters are custom manufactured to suit your grain or product handling needs.

Grain Augers and Screw Conveyors

Grain augers and screw conveyors can be customised to feed product into your mixer, storage bin or silo. Sizes range from 100mm (4″ ) through to 330mm (13″) diameter.

They can also be built for overhead filling of silos, complete with pneumatic slide gates and infeed hoppers. Variations can include inground pit hoppers and ‘A’ framed supports. All augers and screw conveyors are designed and manufactured to compliment your grain handling storage or feed requirements.

We also stock a full range of auger flighting and barrel, as well as stainless steel and heavy duty segmented flighting for industrial applications.

For more info see Jas Smith

Roller Mills

Our Roller Mills range from the 30kg/hr capacity through to the robust 5 tonne/hr machines. The smaller 3 models of our range – 30kg, 180kg, 600kg/hr machines operate with 240 volt power and a 3 pin plug (10 – 15 amp plug depending on model).

These machines are very easy to use, compact and can crush or crack a variety of grains including oats, wheat, and lupins. They are based on a finger inter-meshing type adjustable rollers.

For more info see Jas Smith

Hammer Mills

We have 3 different sizes of Hammer Mills including our 10”, 18” & 20” Hammer Mills. Machines can be powered with either a PTO or with a 3 phase electric motor, and options of grain hopper only, or grain hopper and hay chute feed inlets.

For more info see Jas Smith

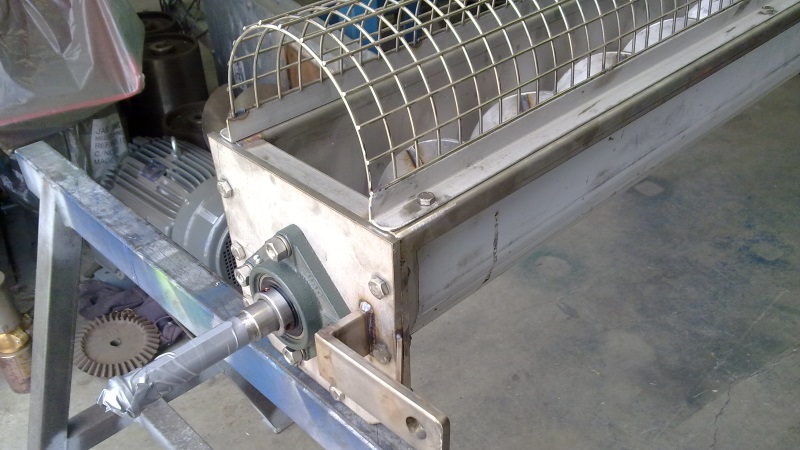

Seed Mixers

Our Mixers can be manufactured as part of a feed plant with the incorporation of a Roller Mill or Hammer Mill, and concentrate feed-in hopper. Our feed mixers include a clean out door to enable full cleaning at the bottom of the auger, and ensuring no contamination of grains between mixes.

The larger 2 ½ and 5 tonne machines can also be combined with a feed mixer with or without load cells to make a complete processing plant to suit your needs. Due to their robust build, solid grooved hollow bar rollers, and large capacity these roller mills are sold to the dairy industry or large horse studs where high volumes or grain are processed daily.

We also sell scales with LCD read out displays and reliable Newlong Bag Sewing Machines.

For more info see Jas Smith